Surface finishing of aluminum

Anodizing and powder coating for aluminum profiles. For corrosion protection and decorative finish

Anodising

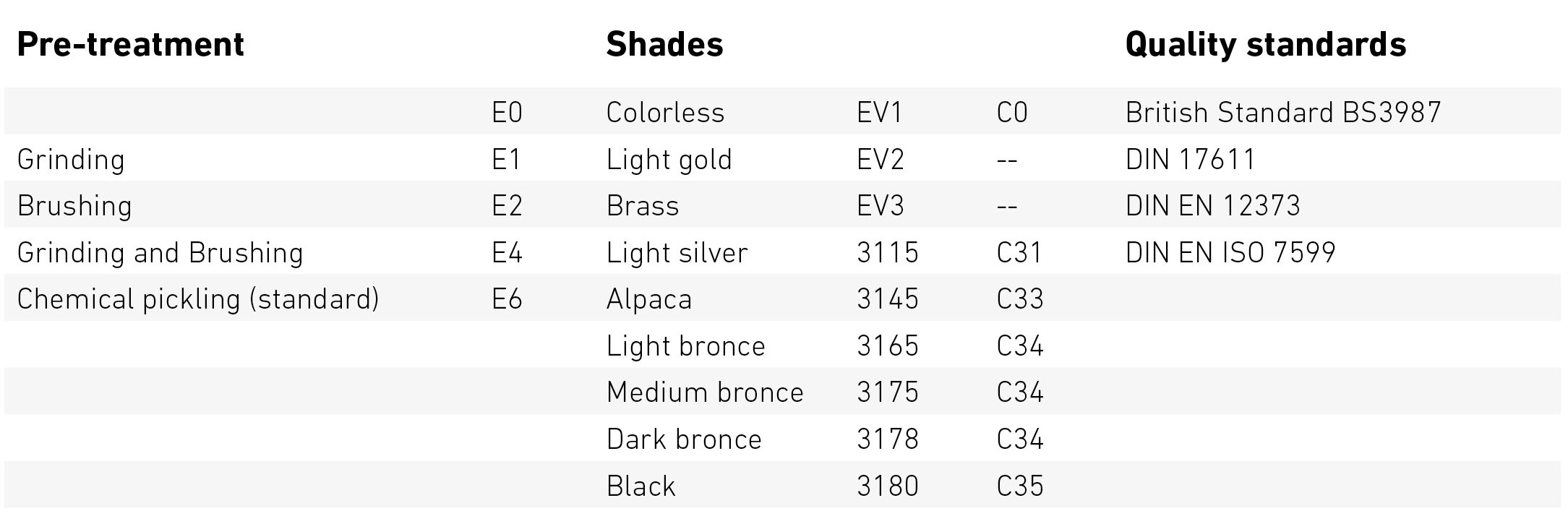

By transforming the surface of the aluminium, we create a corrosion-resistant material with a decorative effect. In an electrochemical process, an oxide layer builds up on the surface of the workpiece, the thickness of which can range from 5 µm to 25 µm. During the anodization process, we can even change the colour of the surface. The colourless anodised layer can be coloured in light gold, bronze or black, in an electrolytic two-step process. With two state-of-the-art anodising lines we carry out all standard surface finishes for manufacturing lengths of up to 7,400 millimetres or for individual anodised pieces.

Powder coating

The powder coating refines your product and provides lasting protection against environmental influences and mechanical loads. The coating is added in a special electrostatic process. It is environmentally friendly and offers almost limitless possibilities.

You can also choose the colour to meet your decorative requirements. In addition to standard RAL shades, we also offer special shades and coatings, such as metallic powder coatings, and shades from the NCS system and the Sikkens palette. All powder-coated surfaces are easy to maintain and fulfil all applicable GSB and Qualicoat standards.

We were also one of the first in the industry to switch to chromium-free passivation, an environmentally friendly procedure for the pre-treatment of the product that is to be coated.